Blown process

Glass blowing is the best known process. The molten glass gob falls into the press mould. A plunger presses the gob into the desired shape and transfers it to a rotating blowing mould to obtain its final shape.

Arc Customised Glass uses different manufacturing processes and materials, including some technologies developed in-house.

Glass blowing is the best known process. The molten glass gob falls into the press mould. A plunger presses the gob into the desired shape and transfers it to a rotating blowing mould to obtain its final shape.

The molten glass gob falls directly into a finishing mould instead of going through a pressed mould.

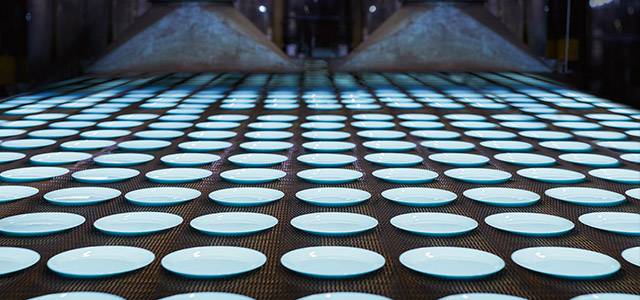

The same result than a product made using the press process can be obtained by depositing a drop in the center of a mould that starts to spin faster and faster. This process gives plates and dishes a faultless interior surface quality.

Goblets or stemmed glasses are usually made in 2 parts. The upper part, the bowl, and the stem. It takes about 3 hours to make a stemmed glass.

A new generation of the lead-free crystal. It has the IWA Ultra clear standard, which guarantees its excellent transparency : a standard that establishes the requirements for the designation “ultra-clear glass” based on the clarity and iron content of the product. Always bright, the rim has a 30% higher than average impact resistance and twice the average resistance of the leg to torsion.

Non-porous material with no bacterial risk. It is 2 to 3 times more resistant than traditional hotel porcelain and can withstand a thermal shock of 130°C/265°F. In addition, the surface and decoration are extremely resistant, even after 2,000 industrial washes and items are microwave safe. Finally, its light weight and the fact that it is stackable allow to save space.

Strong and built to last, tempered products are 5 times more resistant than most products of similar thickness.

Glass in its purest form. This certifies that these items are made with only the highest quality glass. Due to its composition and laboratory-tested performance, the glass features an exceptional level of purity.

Discover the different catalogues.